0086-533-8180355

No.567,Changzheng Road,Zibo City, Shan Dong Province.

0086-18560262888

CONTACT US

0086-533-8161095

HOTLINE

0086-533-8180355

Add: No.567,Changzheng Road,Zibo City, Shan Dong Province.

Mobile: 0086-18560262888

Phone: 0086-533-8161095

Email: gpc@pensc.com

COPYRIGHT © 2019 Shandong Pengcheng Ceramic New Material Technology Co., Ltd. 鲁ICP备11002055号-2 国际站建设:中企动力 淄博

PRODUCTS CENTER

PENSC ceramic evaporation boat

|

THE MOST ADVANCED PRODUCTION TECHNOLOGY

Using the most advanced production equipment and technology to improve the long-term stability of the product, the products have a world-class performance and quality, to meet the production of metallized film, paper, textiles and other materials, widely used in the vacuum evaporation packaging materials, capacitor metal vacuum coating, paper, aluminum plating, bronzing coating, anti-counterfeit labels such as aluminum plating industry. |

|

WORLD-CLASS PERFORMANCE AND QUALITY ◐A shorter pre-heating time> ◐The molten aluminum is easier to spreading wetting ◐Less spitting and bending of the boats problems ◐Longer working life ◐Cost-efficient choice |

|

PRODUCT FEATURES AND ADVANTAGES

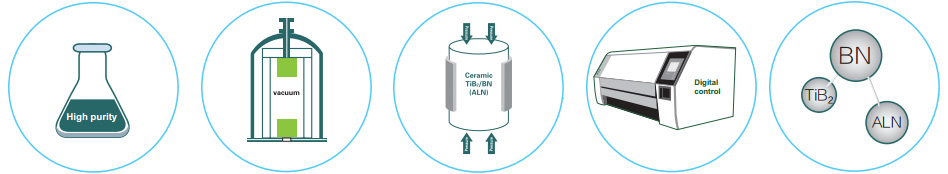

◐Using the high purity raw materials; ensure the material has the best chemical property. Pressed with two-way, ensure the ceramics have consistent volume density properties.

◐Adopt international advanced vacuum hot pressing sintering; ensure the evaporation boat materials have stable physical properties.

◐Pressed with two-way, ensure the ceramics have consistent volume density properties.

◐Production equipment digital control to ensure stable and reliable product quality.

◐A unique formulation process and optimum composition, the evaporation boats enhance high thermal shock resistance and breaking strength. Increased the molten aluminum spreading, evaporation efficiency, resist molten aluminum corrosion and extend the working time.

|

The typical characteristics |

PENSC-BN-T |

|

|

Chemical composition |

BN+TiB2+AlN |

|

|

Density |

g/cm3 |

>3.01 |

|

Modulus of elasticity |

Gpa |

60-70 |

|

Flexural Strength |

Mpa |

>150 |

|

Coefficient of thermal expansion |

(10-6/K) |

4-6 |

|

Thermal conductivity at 20℃ |

W/mk |

100/40 |

|

MAX-Temperature of use |

oxidizing |

900℃ |

|

vacuum |

1700℃ |

|

|

氛inert |

2000℃ |

|

|

RT Resistivity |

μΩ.cm |

300-2000 |