0086-533-8180355

No.567,Changzheng Road,Zibo City, Shan Dong Province.

0086-18560262888

CONTACT US

0086-533-8161095

HOTLINE

0086-533-8180355

Add: No.567,Changzheng Road,Zibo City, Shan Dong Province.

Mobile: 0086-18560262888

Phone: 0086-533-8161095

Email: gpc@pensc.com

COPYRIGHT © 2019 Shandong Pengcheng Ceramic New Material Technology Co., Ltd. 鲁ICP备11002055号-2 国际站建设:中企动力 淄博

PRODUCTS CENTER

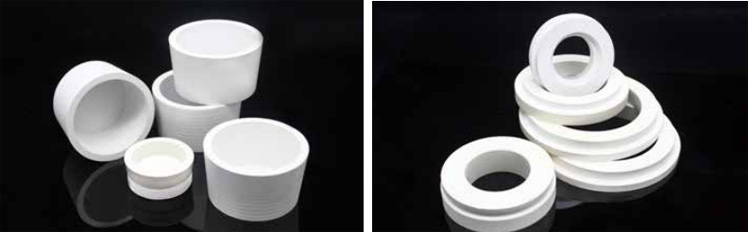

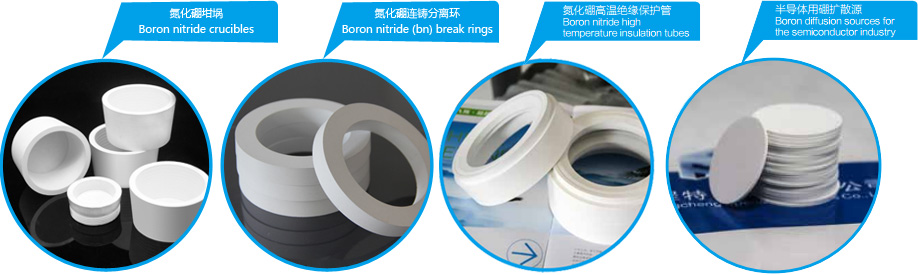

Boron nitride ceramic

BORON NITRIDE CERAMIC PRODUCTS DESCRIPTION

PENSC hot-pressed hexagonal Boron Nitride Ceramic Products, exhibits a unique combination of chemical,electrical,mechanical and thermal properties, making it suitable for a wide range of highperformance industrial applications. PENSC can supply the high purity or include difference binder boron nitride ceramics, complete solution based on kinds of industry customers demand.

FEATURES /BENEFITS

● Excellent thermostable performance (Temperature ≥ 2000℃ in Vacuum and inert atmosphere)

● High thermal conductivity

● Low thermal expansion, excellent thermal shock resistance.

● Outstanding electrical insulation properties at high temperatures.

● High wet resistance to molten metals,slags and glass.

● Extreme corrosion and wear resistance.

● Easily machinable to desired shapes and size.

KEY APPLICATIONS

● Insulators for high-temperature furnaces.

● Amorphous system nozzles and Powder metal atomization nozzle

● High temperature mechanical components such as bearing,valves,spacers.

● Crucibles and molds for molten metal processing.

● Separating Ring for Horizontal Concasting.

● Muffles and crucibles for Nitride and Sialon firing.

● P-Tpye diffusion sources for the semiconductor industry.

Boron nitride ceramic product performance technical parameter table

|

Grade |

|

PENSC-A |

PENSC-AA |

|

Chemical structure |

% |

99 |

99.5 |

|

components |

|

no |

no |

|

Density |

g/cm3 |

1.9-2.0 |

1.55-1.65 |

|

Hardness |

HL |

300 |

300 |

|

Flexural Strength |

Mpa |

35 |

33 |

|

Coefficient of thermal expansion |

(10-6/K) |

-1~2.5 |

-1~2 |

|

Thermal conductivity at 20℃ |

W/mk |

40 |

60 |

|

emperature of use |

oxidizing |

900℃ |

900℃ |

|

vacuum |

1800℃ |

1800℃ |

|

|

不活性ガスinert |

2200℃ |

2200℃ |

|

|

Resistivity |

Ω.cm |

>1014 |

>1014 |

|

Grade |

|

PENSC-T |

PENSC-E1 |

PENSC-E2 |

PENSC-L |

PENSC-N |

PENSC-S |

|

Main ingredients |

|

BN+TiB2+AlN |

BN+ZrO2+SiC |

BN+ZrO2+SiC |

BN+AlN |

BN+Si3 N4 |

BN+ SiO2 |

|

Density |

g/cm3 |

3.01 |

2.3-2.35 |

2.6-2.7 |

2.8-2.9 |

2.5-2.6 |

2.1-2.15

|

|

Hardness |

HL |

|

570-620 |

520-550 |

≥650 |

650-680 |

700-750 |

|

Flexural Strength |

Mpa |

155 |

160 |

150 |

250-300 |

280 |

75 |

|

Coefficient of thermal expansion |

(10-6/K) |

6.0-7.0 |

2.0-3.0 |

3.0-5.0 |

4.0-5.0 |

2.5-3.0 |

2.5-3.0 |

|

Thermal conductivity at 20℃ |

W/mk |

40 |

15 |

30 |

65 |

45 |

20 |

|

Temperature of use |

oxidizing |

950℃ |

900℃ |

900℃ |

950℃ |

950℃ |

1000℃+ |

|

inert |

2000℃ |

1700℃ |

1700℃ |

2000℃ |

1700℃ |

1000℃+ |

|

|

|

Ω .cm |

250-1000 uμ |

> 1012 |

> 1012 |

> 1014 |

> 1014 |

> 1014 |

MACHINING CONSIDERATIONS

PENSC Solid Boron Nitride Grades A,B,C,D and E are truly machinable ceramics, according to the need to produce complicated

shape in little tolerance. Boron Nitride Solids Machining Considerations as follows:

● PENSC Solid Boron Nitride Grades A,B,C,D can be machined using standard high-speed tool steel cutting tools. Carbide tipped tooling is recommended for maching Grades E and Composite materail.

● Machining by grinding may be done if preferred. Threads can be machined using standard taps and dies.

● Cutting oils and coolants are not necessary and should not be used.

● Cutting tools should be sharp and clean and cutting tools with negative rake angles should never be used.

● Care should be taken when chucking and clamping so that excessive pressure is not exerted. Climb milling techniques should be used to prevent corner and edge.

● Boron Nitride solids be kept dry at all time , stored in airtight bags, containers or in dry ovens.

PENSC machining center have many sets of CNC lathe,CNC milling machine. We have rich experience in processing and can produce kinds of bn products according customer requirement.